The presence of arsenic in water especially drinking water, is a huge problem affecting millions worldwide. Arsenic is poisonous and carcinogenic and can particularly damage developing fetuses and young children. The most common cause is groundwater with high levels of naturally-occurring minerals, but agricultural runoff and industrial waste also can be significant contributors. Hence, it’s vital to eliminate this toxic substance from your drinking water. And while there are many technologies currently under research and development, granular ferric hydroxide adsorption technology has emerged as one of the best solutions. Here are five reasons why adsorption on ferric hydroxide granules should be your first choice.

-

It’s Highly Effective in Removing Arsenic

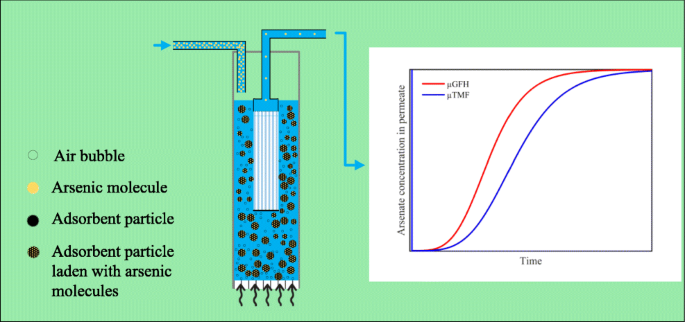

The granular ferric hydroxide adsorption technology is highly effective in arsenic water treatment. The technique effectively removes both forms of arsenic; arsenate, As (V), and arsenite, AS (III). It removes arsenic from water to undetectable levels below 10µg/l as the arsenic in water binds on the surface of the iron-hydroxide adsorbents through a process known as adsorption. It’s crucial to note that the traditional activated alumina adsorbent material has low capacity and high toxicity.

For example, 1 gram of activated alumina can remove only 3 – 4 mg of arsenic. By contrast, 1 gram of granular ferric hydroxide can remove up to 300 mg of arsenic. In other words, you will need 100 times more activated alumina than ferric hydroxide granules if you want to achieve the same results! Therefore, adsorption on ferric hydroxide is much more efficient and safe. Even better, it removes all types of arsenic, including organic arsenic compounds prevalent in many natural water sources worldwide.

-

It Does Not Generate Secondary Waste Streams

One of the best reasons to use granular ferric hydroxide adsorption technology is that it does not generate secondary waste streams. That means that once water passes through the adsorbent media, there are no toxic or harmful byproducts, like sludge or sediment.

Hence, it doesn’t create any hazardous waste products due to its use. That way, you eliminate the risk of disposing of large amounts of sludge and contaminated material without worrying about creating any hazardous materials during your arsenic removal process.

-

No Chemical Use

The use of granular ferric hydroxide adsorption technology for arsenic removal in drinking water is becoming increasingly popular due to its safety, effectiveness, and affordability. One of the main advantages of this technology is that it does not require any chemicals. Instead, the adsorbent granules consist of iron hydroxides, which naturally bind to the arsenic molecules in water.

The binding process requires no added chemical components, making it a safe and eco-friendly solution for drinking water treatment. Its ability to remove 99% of total arsenic particles without using any chemical compounds makes it an excellent choice for protecting public health and preserving the environment.

-

Does Not Affect the Natural Composition of Water

When it comes to removing arsenic from drinking water, many people are looking for a solution that does not affect the water’s natural composition. That is why granular ferric hydroxide adsorption technology is the best choice. Using ferric hydroxide granules in adsorption is an advanced water treatment technology that uses iron-based particles to capture and remove arsenic from the water supply selectively.

Thus, unlike other methods, such as ion exchange, adsorption on granular ferric hydroxide does not change the physical properties or composition of the water in any way. That means the process does not release additional substances, chemicals, or byproducts into the water after treatment. That makes the technique the ideal solution for removing arsenic from drinking water. Not only is it an effective way to remove contaminants, but it also preserves the water’s natural composition, which is essential for providing clean, safe drinking water.

-

Complies with the International Standards

Granular Ferric Hydroxide adsorption technology is a reliable and effective method for removing arsenic from drinking water. It is one of the few technologies that meet the standards of the WHO and the U.S. Environmental Protection Agency (EPA). The WHO recommends that the maximum arsenic concentrations in drinking water be ten micrograms per liter. At the same time, the EPA requires a safe maximum contaminant level of ten parts per billion (ppb).

The adsorption technique on granular ferric hydroxide can quickly meet these requirements, ensuring your drinking water’s safety. That makes it an ideal solution for drinking water treatment applications, especially for areas where arsenic levels are too high for conventional water treatment technologies to reduce them effectively.

Conclusion

Granular ferric hydroxide adsorption technology is a powerful, safe, easy-to-use, and effective method for removing arsenic from drinking water. Its proven efficacy in eliminating arsenic from potable water makes it an ideal solution for municipalities, water districts, and water systems worldwide. Its long-shelf life, minimal maintenance requirements, scalability, and green technology make it a viable option for large and small operations. For these reasons, granular ferric hydroxide adsorption technology is ideal for those looking to ensure their drinking water is free of arsenic. However, it’s crucial to ensure you source this technology from an experienced and reliable water treatment technology company for the best possible experience throughout the chain to the consumer.